Corrosion Mapping in lieu of Radiography

REQUIREMENT

The Middle East based client had a requirement to replace in-service radiographic testing on small bore internally pitted pipework with an automatic encoded ultrasonic system due to the excess site restrictions by their NDT contractor performing onsite industrial radiography.

SOLUTION

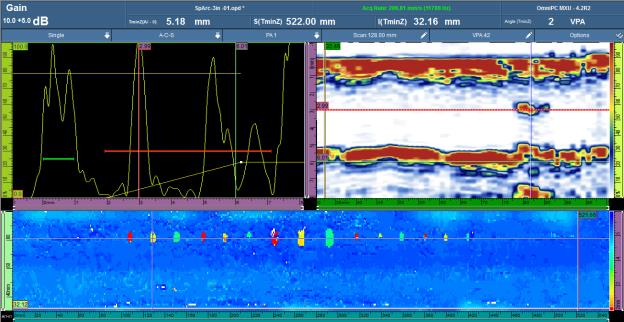

Phased array ultrasonic testing (PAUT) using a curved array for corrosion mapping the small-bore pipework was selected as the automated ultrasonic testing technique for its ability to use multiple elements to steer, focus and scan beams with a single transducer assembly. PAUT also has a higher probability of detection (POD) for internal pitting and corrosion. The inspection speed is greatly reduced with the use of an encoded scanner. A full validation was performed using both manufactured & in-service defects. This was followed by successful onsite trials at one of the client’s gas refineries in the Middle East.